product Description

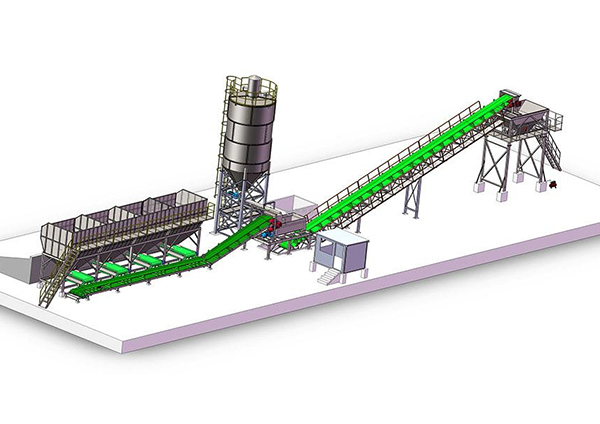

WBZ500 stabilized soil mixing plant can produce various grading stabilized soil mixture, fully meet the requirement of construction in expressway, classified highway, municipal administration path, airports, dams, freight yard, etc.

The stationary stabilized soil mixing plant adopts two-horizontal shafts forced continuous type mixer with a productivity of 300-800t/h. WBZ500 500t/h model is the most popular model.

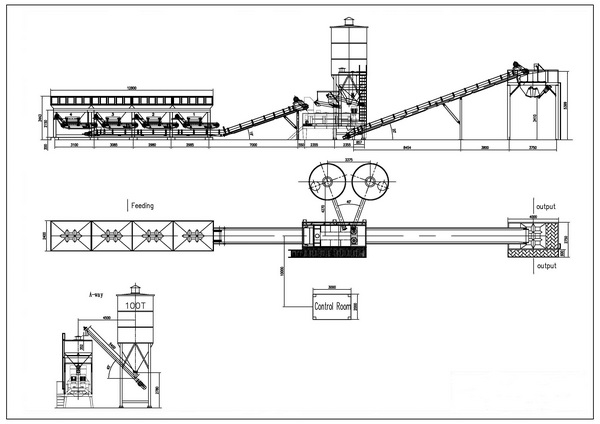

The stabilized soil mixing station is mainly composed of mixing system, batching system, conveying system , finished hopper, weighing system,control system and a cement silo.

Parameter

| Model | WBZ300 | WBZ500 | WBZ600 | WBZ800 |

| Rated production capacity | 300t/H | 500t/H | 600t/H | 800t/H |

| Total power | 110KW | 158KW | 168KW | 228KW |

| Type of measuring | Volume | Volume | Volume | Volume |

| Aggregate | ±3% | ±3% | ±3% | ±3% |

| Soil | ±2% | ±2% | ±2% | ±2% |

| Lime powder, Coal ash | ±1% | ±1% | ±1% | ±1% |

| Cement | ±1% | ±1% | ±1% | ±1% |

| Water | ±1.5% | ±1.5% | ±1.5% | ±1.5% |

| Max motor power | 45KW | 75KW | 90KW | 110KW |

| Aggregate Diameter | ≤±60mm | ≤±60mm | ≤±80mm | ≤±100mm |

| Area covered | 45×17㎡ | 50×18㎡ | 52×22㎡ | 58×26㎡ |

| Total weight | 39t | 51t | 54t | 59t |

| Mode ofSpeed regulation | Electromagnetic | Electromagnetic | Electromagnetic | Electromagnetic |

Features

01.

Our plants are modularization designed. Its convenient to take apart, transport, and install. It is in a centralized arrangement and space-saving footprint.

02.

Aggregate batching system adopts electromagnetic governor motor controlled by computer to charge and measuring in a highly accuracy and reliability.

03.

The mixer is two-horizontal shafts forced continuous type with no lining board. The blades are made by hard-wearing chrome alloy with a long service life.

04.

The measuring system uses the special measuring instruments to ensure the measuring accuracy.

05.

All the parts are controlled by computer.

Operating Principle

All aggregates like lime, sand, soil, coal ash, and other materials are loaded into batching hoppers by a loading machine. After measuring, the belt feeder transports the aggregates into a mixing device. Meanwhile, stabilizing powders like lime or cement are transferred from a powder material warehouse to the batch hopper by a spiral conveyor, and then moved to the belt feeder by a powder material feeder. All ingredients then go into the mixing device for final processing. Finally, the feeding belt conveyor takes the final product and delivers it to the storage warehouse.

Factory Strength