product Description

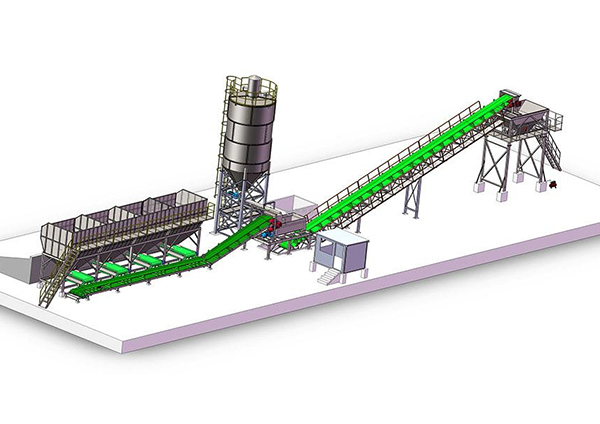

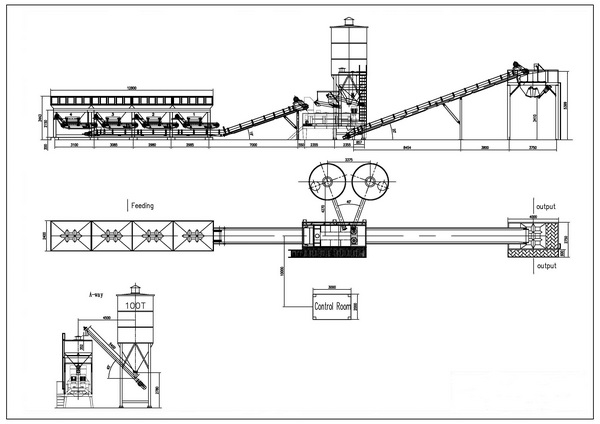

The stabilized soil mixing plant is a combination of kinds of machines used for mixing stabilized soil, lime stabilized earth , gravel and other basic stability of stabilized soil material,which is used for highway construction, municipal road projects, and fertile airport areas. The plant produces stabilized soil with different gradings in a continuous way.

Stabilized soil is a mixture of lime, cement, coal ash, soil, sand, and other aggregates.

The stationary stabilized soil mixing plant have different capacity from 300t/h to 800t/h.

WBZ300 model is the smallest most popular model.

The stabilized soil mixing station is mainly composed of mixing system, batching system, conveying system , finished hopper, weighing system,control system and a cement silo.

- Twin shaft Continuous Mixing System

- Continuous Aggregate batching system

- Belt conveyor system and finished hopper

- Control system

- Cement silo

- Measurement/weighing system

Parameter

| Model | WBZ300 | WBZ500 | WBZ600 | WBZ800 |

| Rated production capacity | 300t/H | 500t/H | 600t/H | 800t/H |

| Total power | 110KW | 158KW | 168KW | 228KW |

| Type of measuring | Volume | Volume | Volume | Volume |

| Aggregate | ±3% | ±3% | ±3% | ±3% |

| Soil | ±2% | ±2% | ±2% | ±2% |

| Lime powder, Coal ash | ±1% | ±1% | ±1% | ±1% |

| Cement | ±1% | ±1% | ±1% | ±1% |

| Water | ±1.5% | ±1.5% | ±1.5% | ±1.5% |

| Max motor power | 45KW | 75KW | 90KW | 110KW |

| Aggregate Diameter | ≤±60mm | ≤±60mm | ≤±80mm | ≤±100mm |

| Area covered | 45×17㎡ | 50×18㎡ | 52×22㎡ | 58×26㎡ |

| Total weight | 39t | 51t | 54t | 59t |

| Mode ofSpeed regulation | Electromagnetic | Electromagnetic | Electromagnetic | Electromagnetic |

Features

01.

Main machine adopts double horizontal continuous non-lining mixer, with uniform mixing and high productivity; reliable and accurate weighing and quick speed of changing matching.

02.

Computer control technology, which allow convenient operation and good reliability.

03.

Speed regulation with saving energy consumption and stepless speed regulation, which completely ensures the reliability of equipment running.

Operating Principle

All aggregates like lime, sand, soil, coal ash, and other materials are loaded into batching hoppers by a loading machine. After measuring, the belt feeder transports the aggregates into a mixing device. Meanwhile, stabilizing powders like lime or cement are transferred from a powder material warehouse to the batch hopper by a spiral conveyor, and then moved to the belt feeder by a powder material feeder. All ingredients then go into the mixing device for final processing. Finally, the feeding belt conveyor takes the final product and delivers it to the storage warehouse.

Factory Strength