product Description

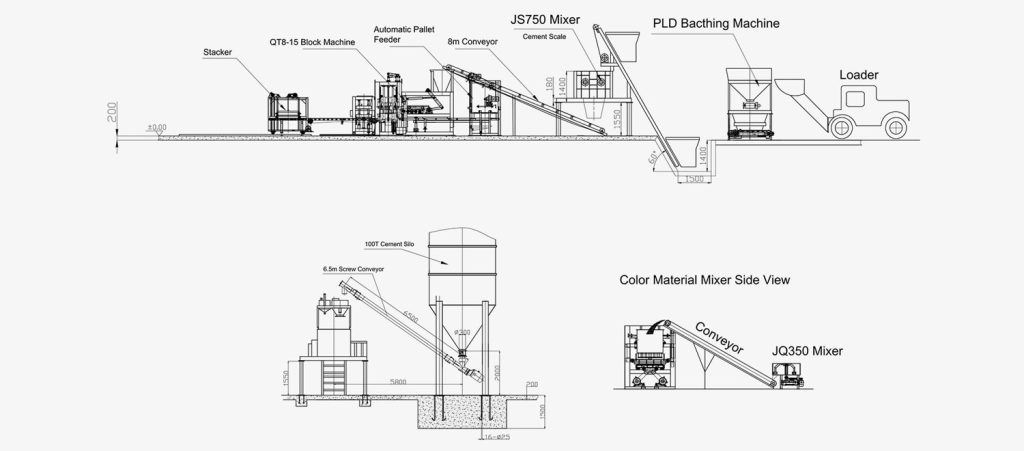

QT8-15 Concrete Block Making Machine is full-automatic hydraulic block machine, which is can be composed into block automatic production line, just equipped with batching plant, concrete mixer, cement silo, main block machine, block stacker. It is controlled by PLC system, which can save labor.

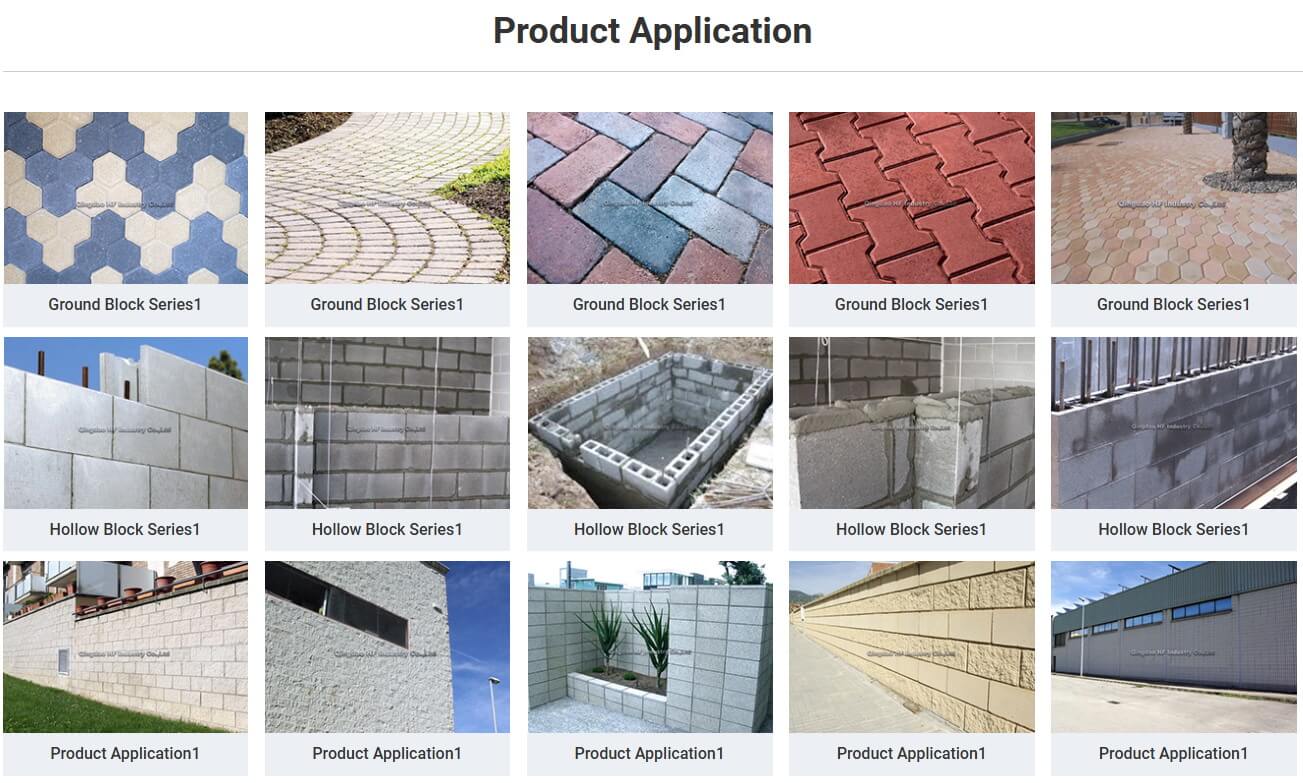

QT8-15 concrete block machine is low investment equipment with high efficiency; it only requires 3 or 4 operators and can produce different types of blocks such as hollow blocks, floor blocks, municipal pavement blocks and etc.

Parameter

| Overall Dimension | 8300x1860x3000mm |

| Rated pressure | 21MPa |

| Main vibration form | Platform vibration |

| Cycle Time | 15-25 seconds |

| Vibrating Frequency | 2800-4500 rolls/minute |

| Pallet Size | 950x900mm |

| Motors Power | 55.5kw |

| Weight | 9700kg |

| Raw Materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applied Products | Concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields | Widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block | 400x200x200 | 15-20 | 8 | 1440-1920 | 11520-15360 | |

| Hollow block | 400x150x200 | 15-20 | 12 | 2160-2880 | 17280-23040 | |

| Solid block | 240x110x70 | 15-17 | 33 | 6988-7920 | 55904-63360 | |

| Paver | 225×112.5×60 | 15-25 | 21 | 3000-3780 | 24000-30240 | |

| Paver | 200x100x60 | 15-25 | 32 | 4600-7680 | 36800-61440 |

Features

- It adopts material storage and distribution system to manage material storage and distribution so as to ensure accurate feed and precise dispensing for even density and high compactness of products.

- It utilizes frequency conversion synchronous vibration mode and the vibration frequency can be adjusted according to different production requirements to attain low-frequency feeding and high-frequency molding. The change of amplitude and vibration frequency in the process of frequency conversion is beneficial for concrete compactness.

- In a variety of data control systems for the production, it is easy and simple to operate and adjust the material changes to produce various products.

- The automatic diagnosis system has alarming function, which can help timely troubleshooting. The remote data monitoring and recovery, system upgrading and fault diagnosis functions can be realized through network connection

Widely Used Raw Materials

The materials choosing are a wide range, such as slag, fly ash, building rubbish, coal gangue, cement, sand, and so on. You just need the correct ratio of materials. Then the concrete block can be of high quality. For example, fly ash block ratio:

Normally: fly ash 50%、gravel 35%、cement 8% and sand 7%

Or fly ash 50%、gravel 42%、cement 8

Factory Strength