product Description

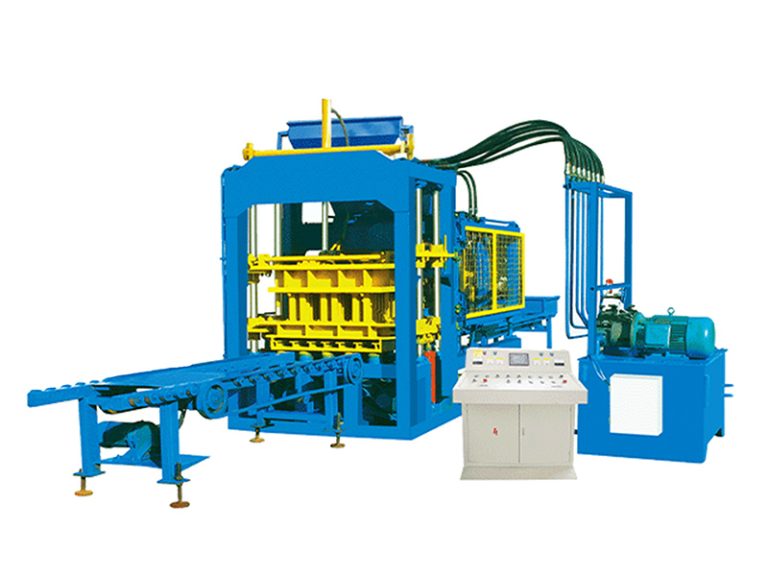

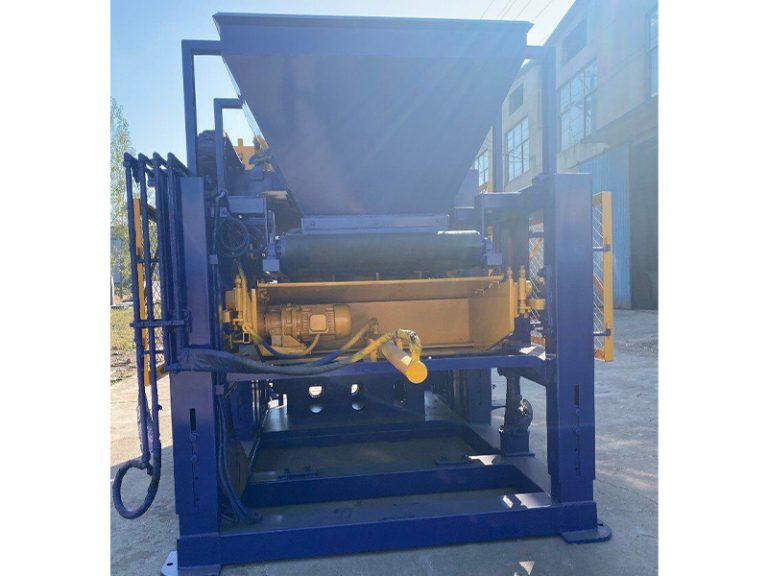

QT6-15 is different from previous hydraulic block machine models. It has a wider body and increases the output by increasing the mold size. We have made a lot of efforts to improve the synchronous and frequency vibration force of the hydraulic block machine.

we adopts our advanced hydraulic system and vibration system, can ensure the block quality very good and the working noise very low. We cooperated with SIEMENS, SCHNEIDER, OMRON, CALYCA and so on to make sure our block machine with high quality and keep our machine work more stable.

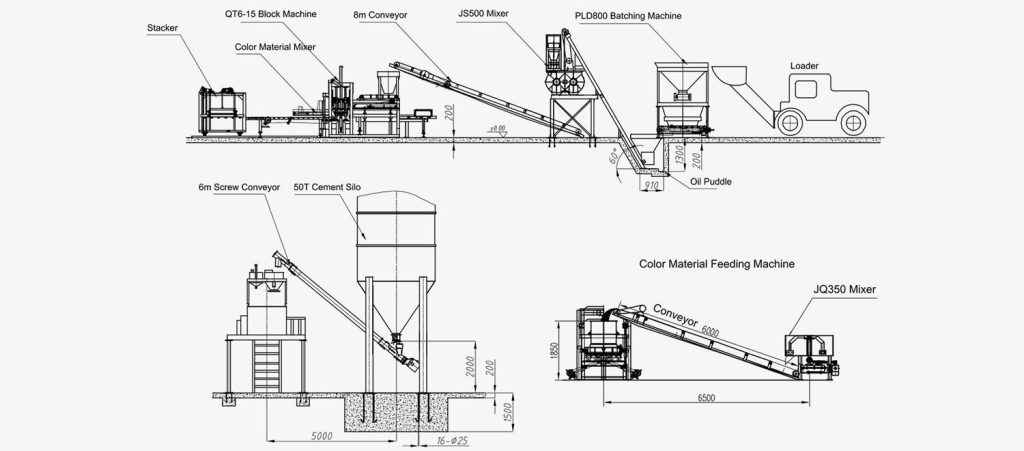

We provide complete technical support, including site planning, installation guidance, technical training and after-sales service.

Parameter

| Dimension of host machine | 3200x2300x2750mm | Host machine power | 45kw |

| Weight of host machine | 85T | Vibration force | 60-80KN |

| Moulding cycle(s) | 15-20 | Mixer model | JS500 |

| Water consumption | 5-8Tonday | Pallet size | 1150x720x25mm |

| workshop area | 250-300 m² | Voltage | adopt to local voltage |

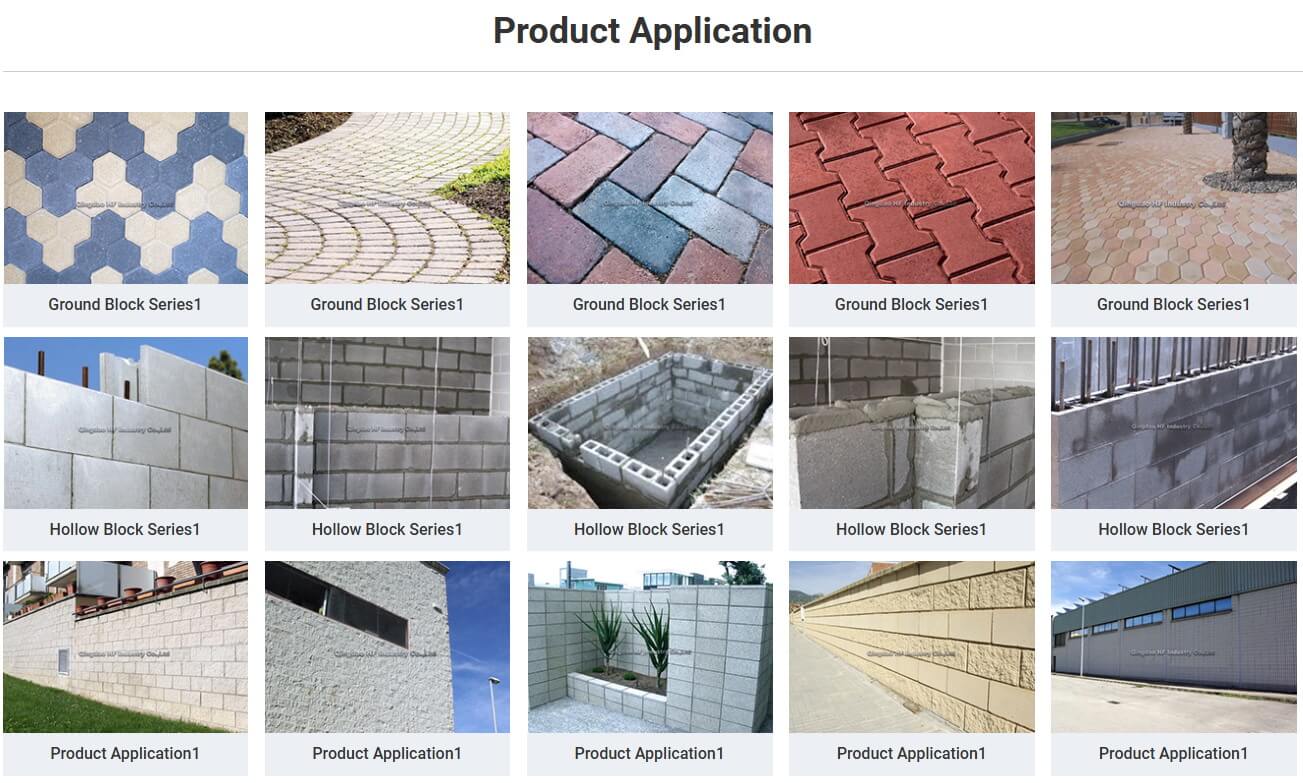

| Name | Size(LxWxH) | Block Making Period | Pcs/Mould | Pcs/Hour |

| Hollow Brick | 400x200x200mm | 15-20s | 5 | 1080-1440 |

| Multi-Hole Brick | 240x115x90mm | 15-20s | 15 | 2700-3600 |

| Solid Brick | 240x115x53mm | 15-20s | 30 | 7200-5400 |

| Paver | 200x100x60mm | 20s | 21 | 3780 |

| I shape Paver | 200x163x60mm | 20s | 16 | 2880 |

Features

01.

High Efficiency and energy saving

02.

Super wear-resistant gear, strong vibration

03.

Easy operating and convenient maintenance

04.

Big capacity, automatic PLC operation

- QT6-15 has a unique material storage and batching system to ensure accurate and sufficient feeding, avoid the influence of external temperature, and make the block density high.

- Synchronous vibration is used to ensure uniform molding of products and consistent height of left and right bricks, and the frequency can be changed according to different bricks, low-frequency feeding, and high-frequency vibration so that different materials have the best vibration mode.

- Computer fault diagnosis system, alarm signal, and automatic troubleshooting of machinery, combined with the remote control system, can realize monitoring, control, and diagnosis.

- PLC intelligent control: The human-machine interface, the control system, has complete logic control, production program, fault diagnosis system, and remote control function. Therefore, no professional personnel are required; only simple operator training is required.

- It can produce a variety of bricks/blocks such as colored pavement bricks, interlocking bricks, curb bricks, hydraulic bricks, hollow bricks, porous bricks, standard bricks, etc.

Factory Strength