product Description

Model QT10-15 block making machine, which has big capacity of block production, which can produce 10pcs/mould(400200200mm), only 10-15s can get the block, it is operated without worker.

It is equipped with PLC control system. And all the mould can be made by customers’ drawings. The key parts are famous brand electrical parts, such as Schneider to guarantee good quality. So if you need a high capacity and fully automatic block making machine, the model QT10-15 is the best choice for your block production project.

Parameter

| Overall Dimension | 9350x2520x2950mm |

| Rated pressure | 21MPa |

| Main vibration form | Platform vibration |

| Cycle Time | 15-25 seconds |

| Vibrating Frequency | 2800-4500 rolls/minute |

| Pallet Size | 1150x900mm |

| Motors Power | 63.5kw |

| Weight | 11000kg |

| Raw Materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

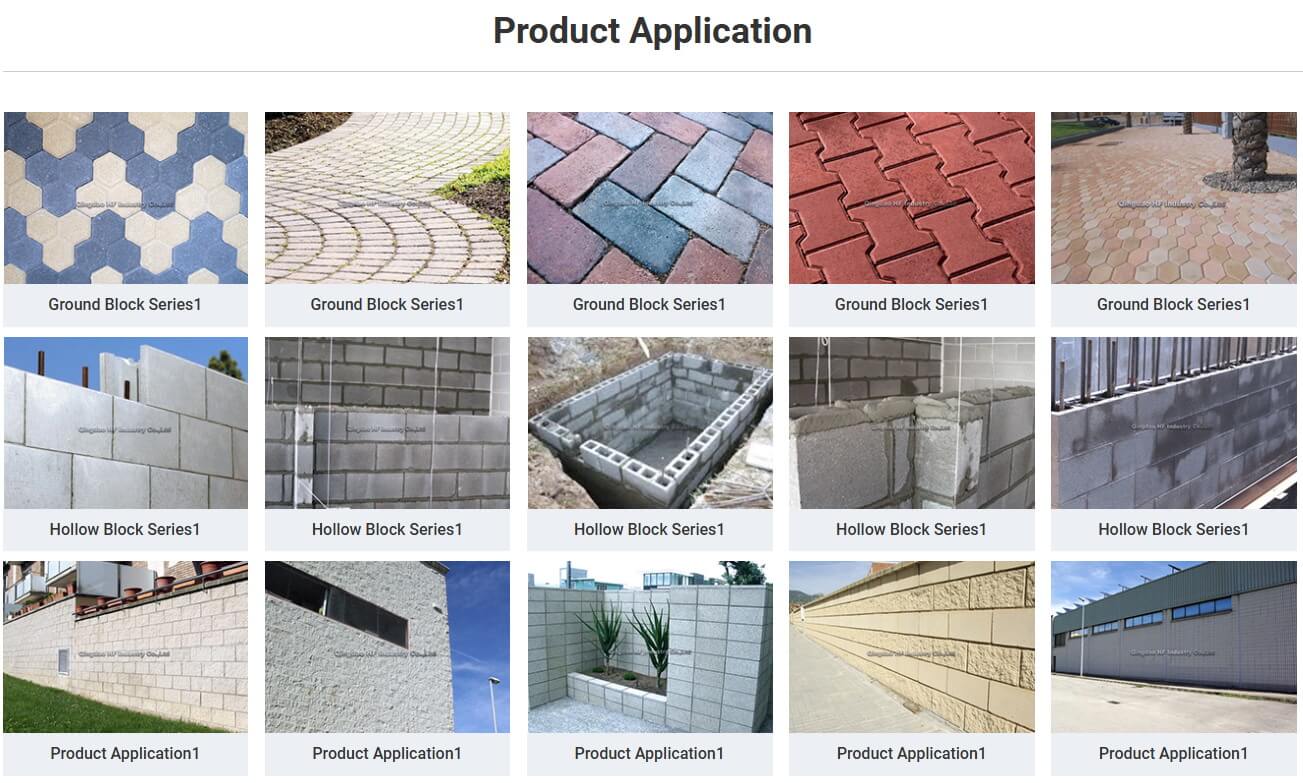

| Applied Products | Concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields | Widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block | 400x200x200 | 15-20 | 10 | 1800-2400 | 14400-19200 | |

| Hollow block | 400x150x200 | 15-20 | 14 | 2520-3360 | 20160-26880 | |

| Solid block | 240x110x70 | 15-17 | 40 | 8470-9600 | 67760-76800 | |

| Paver | 225×112.5×60 | 15-25 | 16 | 3456-5760 | 27648-46080 | |

| Paver | 200x100x60 | 15-25 | 40 | 5760-9600 | 46080-76800 |

Features

- Applies for large block products with maximum height of 400mm.

- It can realize vertical production and optional layered material feeding, which can increase output and get a better appearance of products.

- The forced centrifugal feeding system can prevent concrete liquefaction in advance. The mechanism works and realizes the forced centrifugal discharge so that materials are ready to use immediately after unloading and the material distribution is fast and uniform.

- Four-axis synchronous vibration system integrates computer control, Schneider frequency conversion system, motor drive control and other technologies.

- All of the control apparatus is international brands such as Fuji, Siemens, ABB and Schneider, which can ensure the quality.

- The 25% enhanced vibration system has a good tamping effect for products with ultra-height.

Applications

Factory Strength