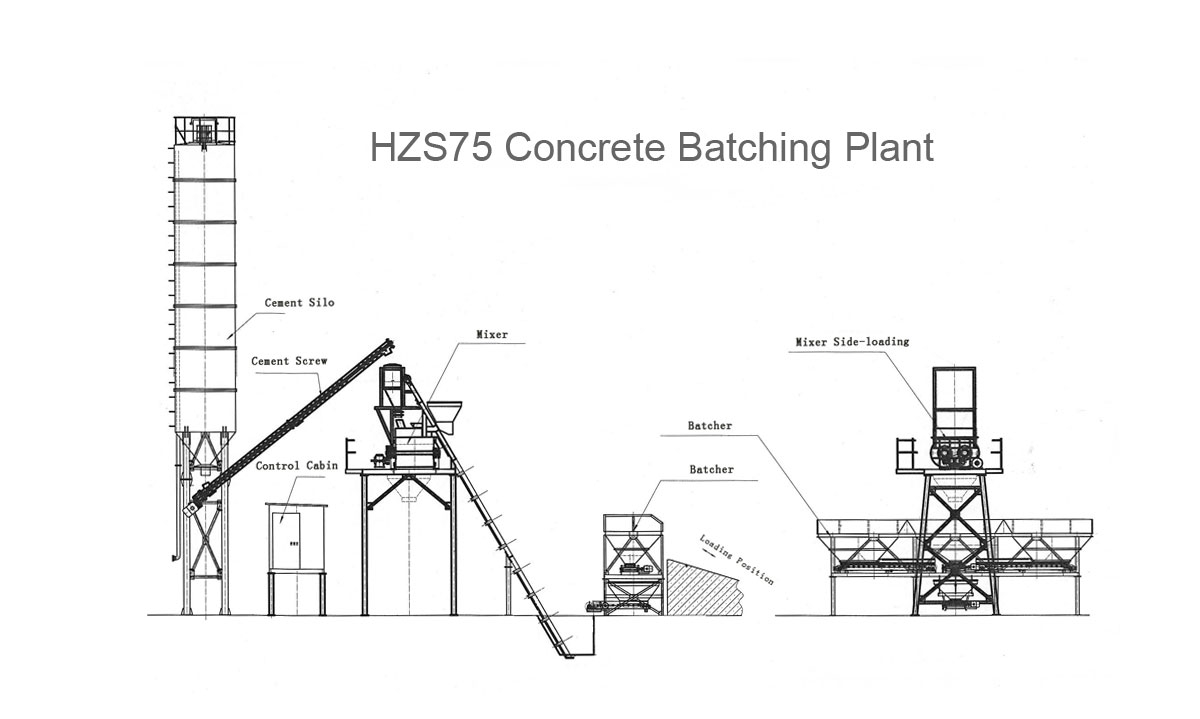

product Description

HZS75 concrete batching plant is the largest model of skip hopper batching plants, with productivity of 75m³/h. It suits for mixing dry hard, half dry hard, plastic, and other ratios of concrete with features of high production efficiency.

It applies in medium-sized or temporary projects, prefabricated parts factories, small commercial concrete plant and so on.

HZS75 Concrete Batching Plant has the advantages of performances such as work stable, compact structure, small footprint, easy transfer, ect.

Parameter

| Model | HZS25 | HZS35 | HZS50 | HZS75 | |

| Global parameter | Max productivity (m³/h) | 25 | 35 | 50 | 75 |

| Discharging height(m) | 1.5–3.8 | 1.6–3.8 | 3.8 | 3.8 | |

| Working cycle time(s) | 72 | 72 | 72 | 72 | |

| Outline dimension(mm) | 11693×13060×17245 | 12922×13000×17245 | 15689×12500×18704 | 17608×12500×18704 | |

| Total Power(kw) | 57.25 | 75 | 88 | 150 | |

| Mixer | Model | JS500 | JS750 | JS1000 | JS1500 |

| Batcher | Model | PLD800 | PLD1200 | PLD1600 | PLD2400 |

| Aggregates feeding Mode | Skip hoist | Skip hoist | Skip hoist | Skip hoist | |

| Pneumatic system | Air compressor | 1.0–7 | 1.0–7 | 1.5–7 | 1.8–7 |

| Discharge pressure(MPa) | 0.8 | 0.8 | 0.8 | 0.8 | |

| Displacement (m³/min) | 1.67 | 1.67 | 1.67 | 1.67 | |

| Motor power | 5.5 | 5.5 | 7.5 | 11 | |

| Measurement system | Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Cement silo Advice | 1x50t | 1x100t | 1x100t | 2x100t | |

| Loading Advice(1silo included) | 1*40HQ container | 1*40HQ container | 2*40HQ containers | 2*40HQ containers | |

Main Components of HZS75 Concrete Batching Plant

HZS75 Concrete Batching Plant is equipped with JS1500 twin-shaft compulsory mixer and PLD2400 aggregate batcher. It transports aggregates with skip hopper(bucket), which saves the footprint. The aggregate batcher can be equipped with 3-5 aggregate bins according to the production requirements. In addition, the fully automatic control system automates the production process, meeting the concrete production requirements of different grades and formulations.

Factory Strength