product Description

HZS60 concrete batching plant is an excellent choice for medium-sized projects. With a production capacity of 60 m³/h, this model provides time and cost savings in your projects with its high mixing performance and fast production cycle.

It is very popular in various projects of buildings, roads, bridges, highway,railway, docks, airport, water projects, hydropower station, etc.

Parameter

| Model | HZS60 | HZS90 | HZS120 | HZS180 | |

| Global parameter | Max productivity (m³/h) | 60 | 90 | 120 | 180 |

| Discharging height(m) | 4.2 | 4.2 | 4.2-4.5 | 4.2-4.5 | |

| Working cycle time(s) | 60 | 60 | 60 | 60 | |

| Outline dimension(mm) | 58445×12376×18704 | 58555×12376×18704 | 60210×13700×18704 | 62900×15000×19500 | |

| Total Power(kw) | 115 | 150 | 210 | 260 | |

| Mixer | Model | JS1000 | JS1500 | JS2000 | JS3000 |

| Batcher | Model | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Aggregates feeding Mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor | |

| Pneumatic system | Air compressor | 1.5–7 | 1.8–7 | 1.8–7 | 1.8–7 |

| Discharge pressure(MPa) | 0.8 | 0.8 | 0.8 | 0.8 | |

| Displacement (m³/min) | 1.67 | 1.67 | 1.67 | 1.67 | |

| Motor power | 7.5 | 11 | 11×2 | 11×2 | |

| Measurement system | Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Cement silos Advice | 2x100t | 3x100t | 4x100t | 4x200t | |

| Loading Advice | 3*40HQ containers | 4*40HQ containers | 6*40HQ containers | 8*40HQ containers | |

Features

01.

Independent and accurate weighing system.

02.

The modular structure is convenient for installing and removing.

03.

High production performance output with high-quality concrete.

04.

Stable Operation &Anti-Interference.

05.

Enviromental Protection (mixer and silo dust removal).

06.

Quick returns.

07.

Long-term online and offline after-sales service (problem solution& parts supply ).

Accessories

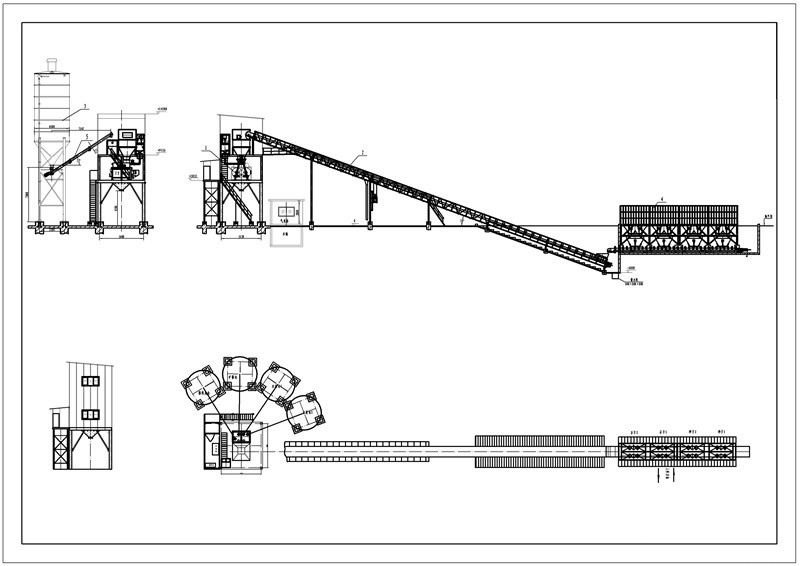

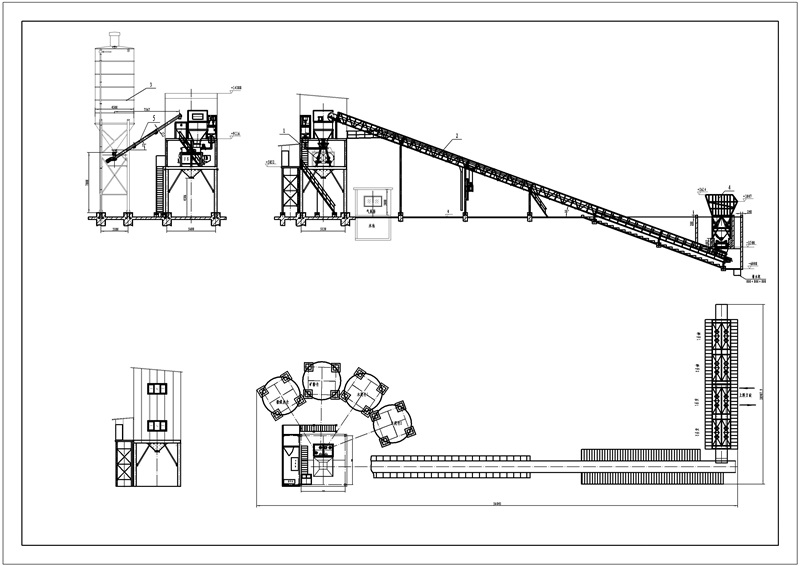

Belt conveyor type concrete batching plant usually consists of aggregates storage and dosing system, cement storage and delivery system, aggregates feeding system, mixing system and control system.

Aggregates (sand and stone) storage and dosing system uses PLD serials concrete batching machine. The aggregates storage usually uses 3-4 bins,with individual weighing hoppers.

Factory Strength