product Description

HZS180 concrete mixing plant can be used as commercial ready-mixed concrete batching plant to sell high quality concrete to different buyers. It is an ideal choice for the production of high-quality concrete with a large amount of demand.

It is widely used in roads, airports, ports, hydropower projects, prefabricated plants and various large-scale construction projects with its powerful production capacity and high mixing efficiency. It can meet the needs of large-scale projects for efficient, stable and continuous production of concrete.

Parameter

| Model | HZS60 | HZS90 | HZS120 | HZS180 | |

| Global parameter | Max productivity (m³/h) | 60 | 90 | 120 | 180 |

| Discharging height(m) | 4.2 | 4.2 | 4.2-4.5 | 4.2-4.5 | |

| Working cycle time(s) | 60 | 60 | 60 | 60 | |

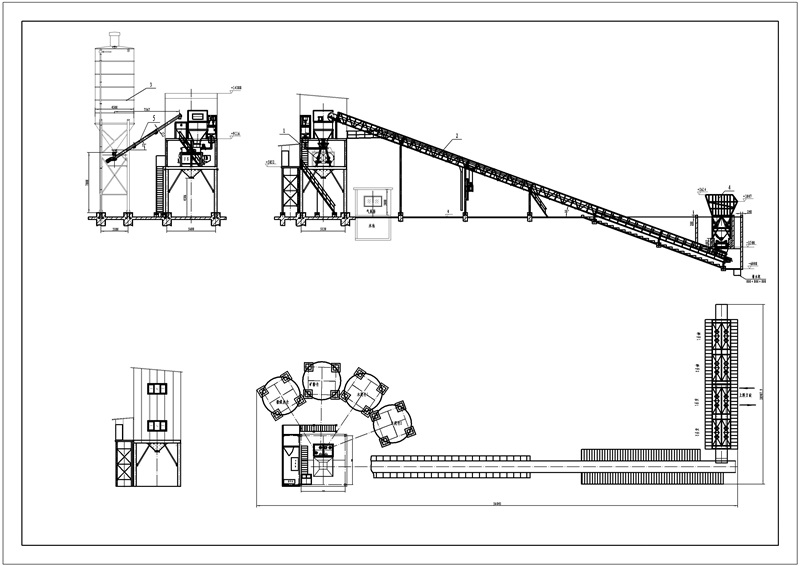

| Outline dimension(mm) | 58445×12376×18704 | 58555×12376×18704 | 60210×13700×18704 | 62900×15000×19500 | |

| Total Power(kw) | 115 | 150 | 210 | 260 | |

| Mixer | Model | JS1000 | JS1500 | JS2000 | JS3000 |

| Batcher | Model | PLD1600 | PLD2400 | PLD3200 | PLD4800 |

| Aggregates feeding Mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor | |

| Pneumatic system | Air compressor | 1.5–7 | 1.8–7 | 1.8–7 | 1.8–7 |

| Discharge pressure(MPa) | 0.8 | 0.8 | 0.8 | 0.8 | |

| Displacement (m³/min) | 1.67 | 1.67 | 1.67 | 1.67 | |

| Motor power | 7.5 | 11 | 11×2 | 11×2 | |

| Measurement system | Aggregate weighing accuracy | ±2% | ±2% | ±2% | ±2% |

| Cement weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Water weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Additive weighing accuracy | ±1% | ±1% | ±1% | ±1% | |

| Cement silos Advice | 2x100t | 3x100t | 4x100t | 4x200t | |

| Loading Advice | 3*40HQ containers | 4*40HQ containers | 6*40HQ containers | 8*40HQ containers | |

Features

01.

High efficiency, low fuel consumption, and environmental care.

02.

Modular function and design; easy installation and site transfer.

03.

Equipped with Italy SICOMA dual-horizontal axis forced type main mixing machine, featuring superior mixing capacity and high reliability.

04.

Independent measuring of various kinds of materials , stable performance and accurate measurement.

05.

Advanced industrial computer + PLC control mode, full automatic control and manual control optional.

06.

It can also be designed according to the requirements and conditions (site, output, environmental care, structural appearance).

Prepare Reserved Cables for each motor are marked with letters, for easy connection

After-sales service will be online support or remote control support, or technician door-to-door service

Accessories

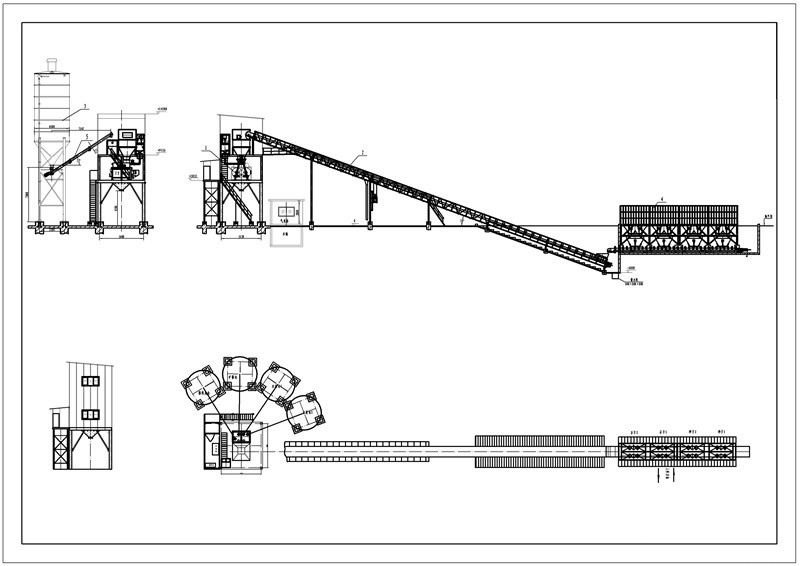

The HZS180 concrete batching plant is composed of mixing system, batching system, belt feeding system, weighing system, pheumatic system, cement silo 150t/200t, automatic control system with control room, and outside packing.

Factory Strength