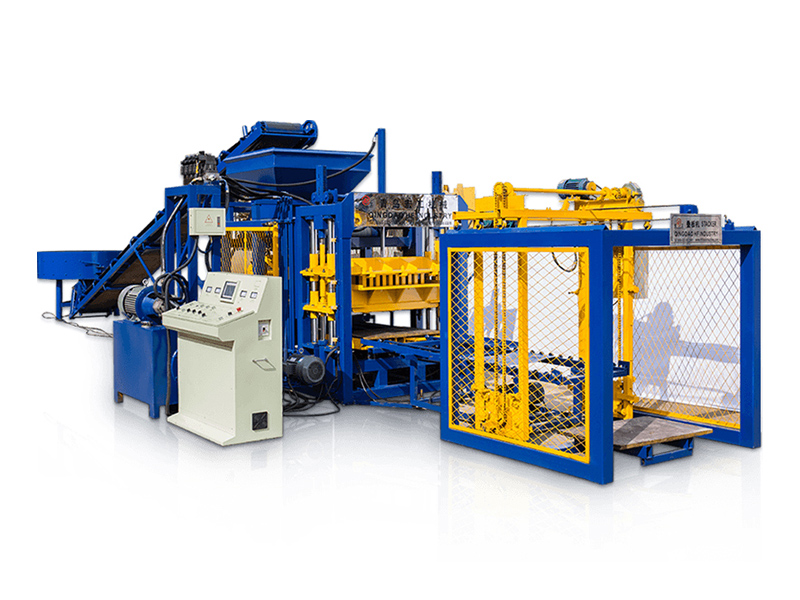

product Description

Concrete mixer pump integrates concrete feeding, mixing and conveying functions seamlessly in one concrete pump machine, the concrete mixer pump can be driven by diesel engine or electric motor as your choice. It is widely used for continuously concrete mixing and conveying through high hydraulic pressure along the pipeline in such applications as housing building, bridge or tunnel construction.

XINFENG concrete mixer pump is made with high wear and strong corrosion resistant chrome alloy steel to greatly improve the product performance, and is optimized by the electric proportional control buffering, pressure difference sensing and reversing technology to decrease high pressure oil pump reversing time.

Our concrete mixer pump is intelligently controlled to achieve the perfect and high efficient concrete mixing and conveying, it features compact structure, stable concrete pumping, energy saving, high efficiency, flexible movement and easy operation, etc.

Parameter

| Model | JBS30 | JBS40 | JBS30R | JBS40R |

| Max. theo. concrete output (m³/h) | 30 | 40 | 30 | 40 |

| Max.concrete mixing amount(m³/h) | 12 | 15 | 12 | 15 |

| Mixer feeding capacity (L) | 550 | 650 | 550 | 650 |

| Mixer discharge capacity(L) | 350 | 450 | 350 | 450 |

| Max.concrete pumping pressure | 10 | 8 | 10 | 8 |

| Distribution valve type | S Valve | S Valve | S Valve | S Valve |

| Concrete cylinder diameter×stroke | Φ140/1000 | Ф180×1100 | Φ140/1000 | Ф180×1100 |

| Type | Electric motor | Diesel Engine | ||

| Hopper capacity | 800 | 800 | 800 | |

| Outlet diameter | Ф100 | Ф150 | Ф100 | Ф150 |

| Dimension (mm) | 4500×2200×2300 | 4500x2200x2800 | 5900x2300x3150 | 6000x2300x3150 |

| Total Weight (kg) | 4500 | 5500 | 5500 | 6000 |

Features

- Perfect combining concrete mixing with conveying in one machine.

- Diesel concrete mixer pump and electrical concrete mixer pump are available.

- Hydraulic double-cylinder piston system, more stable concrete flowing and pumping.

- Mortar stop pressure relief valve, pumping cleaning ball washing, more secure and faster cleaning operation.

- Advanced hydraulic system.

- Adaptive gear adjustment technology, smart matching of operating conditions.

- Automatic and intensive lubrication system ensures effective lubrication during the operation.

- Improved Hopper, high effectivity.

- Powerful mixing ability.

- High reliability and wear resistance components, imported brand main hydraulic components.

- SYMC intelligent controller, high-speed and reliable operation.

- Compact structure, flexible to operate.

Factory Strength